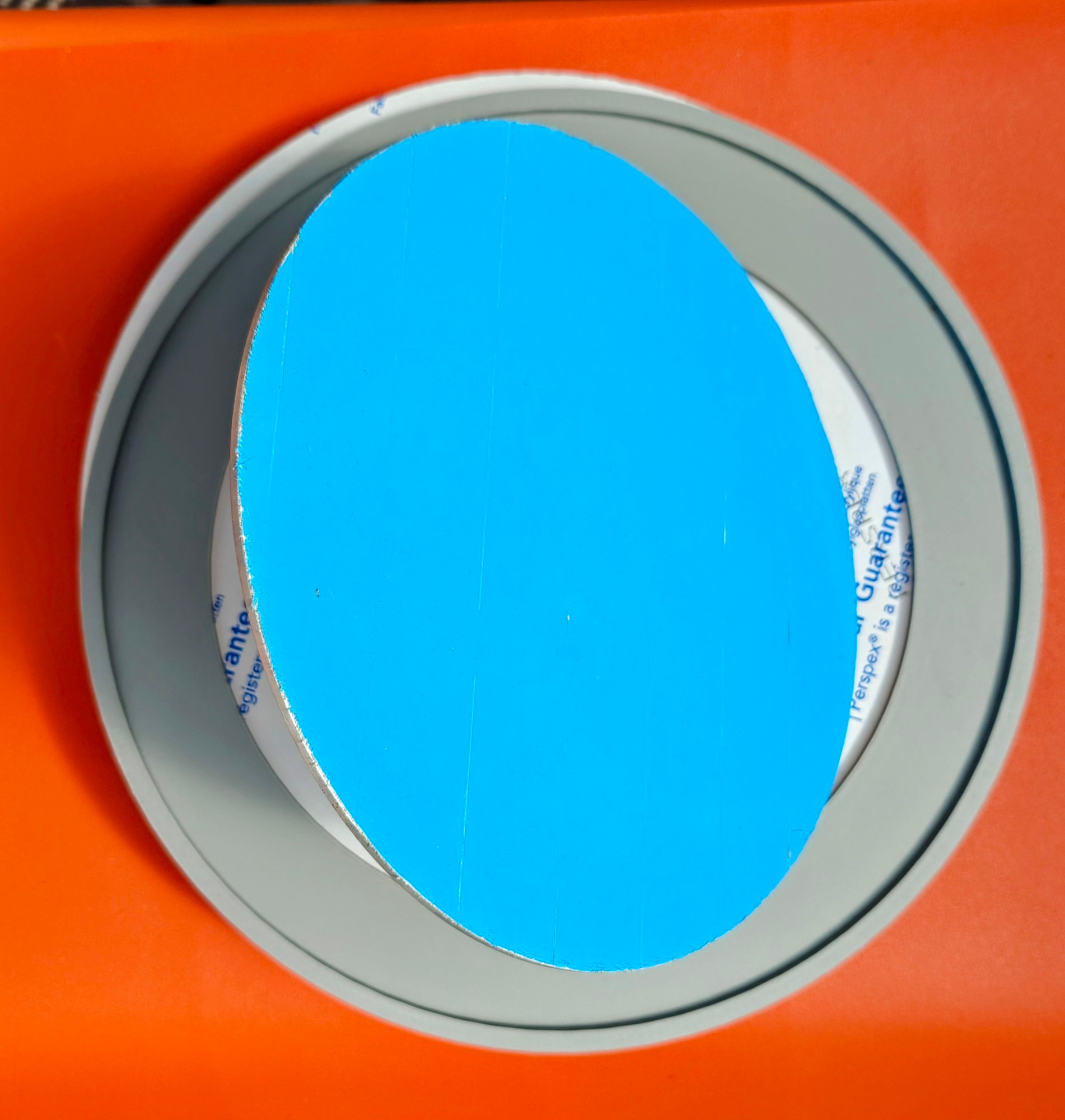

I'm going to go for another FatScreen build but this time, it'll be using a 10.4 inch screen.

The lens I'll need to build will only just fit in the lathe and it'll need to be spot on centered.

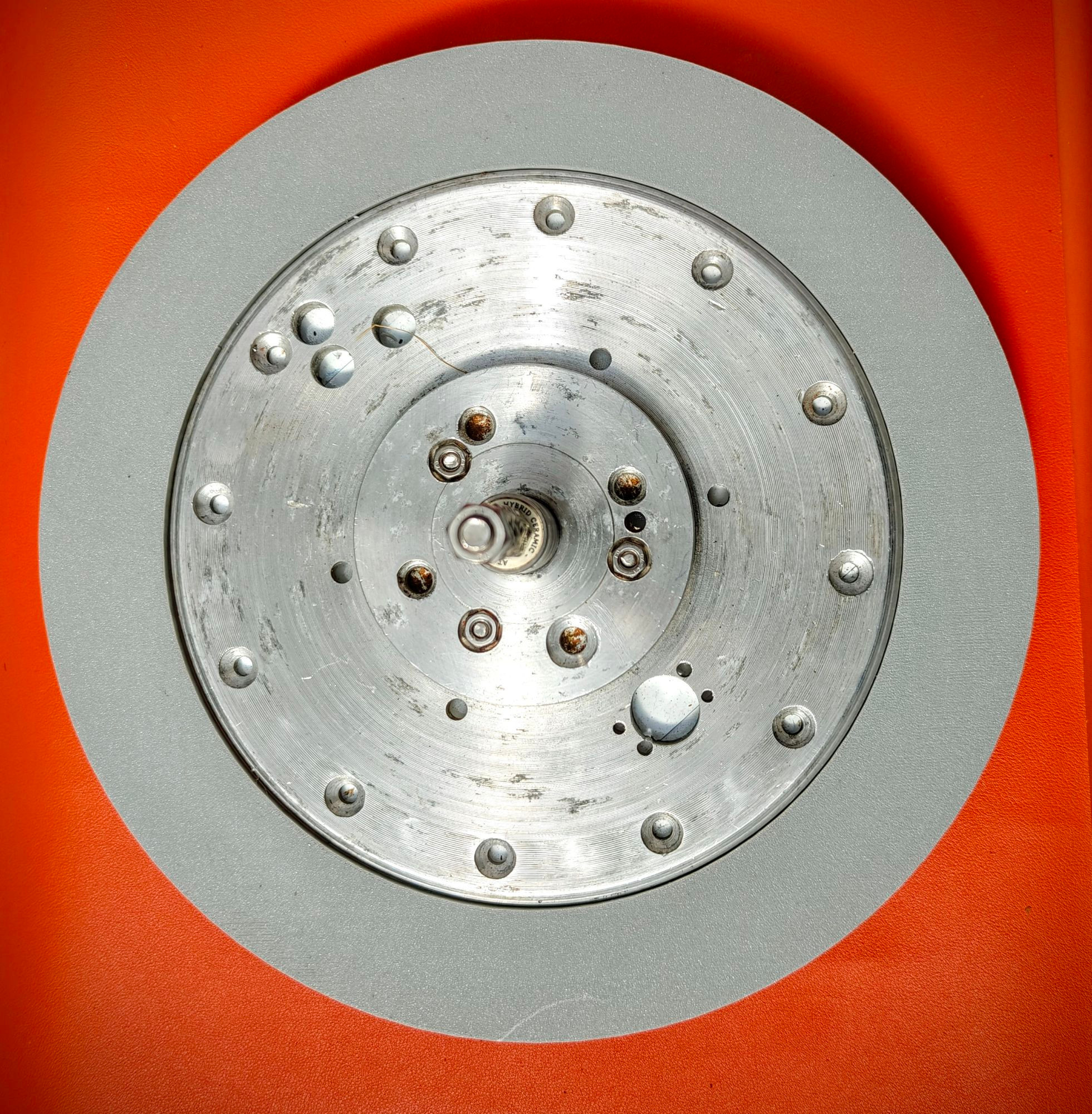

I've got a spinning arbour and used a 3d printed guide to stick them together with thermal tape. 🙂

The lens I'll need to build will only just fit in the lathe and it'll need to be spot on centered.

I've got a spinning arbour and used a 3d printed guide to stick them together with thermal tape. 🙂

1 / 3

Comments

I've always had a healthy fear of my lathe, and it makes my bits twitch each time I power it up. This is nearly 2kg, the biggest thing I've ever put in the chuck so I'll septuple check everything. 🙂

I have had this idea for a miniature Osborne 1. The core would use an RP2040 to run CPM.

I'll be roughing it out for a while, I made a custom bit for acrylic that cuts like butter and fires the excess material in a reasonably predictable direction. 🙂

I'm using up old rattle can tins as a marker so I just need to trim the marked areas, rinse and repeat.

I have a new idea for the final lens shaping that I'm keen to try. 🙂

I have a plan for the shell and it'll need a lot to go right but it'll be worth it if I can pull it off. 🤞

The idea is to offset the axis and it 'should' spin the material and hone it into the final shape.

The theory is sound anyway. 🙂

I'll keep an eye on it as I have a track record of forgetting something fundamental, usually with hilariously disastrous consequences. 😂

Wish I had your skills